How long can chemicals be stored?

APVMA registration requires accelerated storage testing of product equivalent to 2 years. However chemical quality can be maintained much longer.

Good storage is a critically important in maintaining chemical quality. Some changes might be cosmetic but other attributes can significantly change performance of a chemical.

Symptoms of Change

Changes of product over time might be seen as;

Colour: Dyes can fade in direct sunlight like Glyphosate. Some chemicals are photosensitive eg. Prosulfocarb, Metolachlor. These changes are usually cosmetic.

Active ingredient decline: Examples of chemicals more prone to this are Esters, Dimethoate, Butroxydim. In good storage the change may only be minimal

Separation: Could be overcome with good mixing. A thin layer at the top of a SC is perfectly normal

Fall Out: Sometimes seen as crystals in poor quality Glyphosate or Trifluralin and formed in cold conditions. Other products could have precipitate of active on bottom of drum that is difficult to resuspend even with agitation.

Physical Attributes: Flaking, formation of lumps, product setting hard

Causes of degradation

Degradation of chemical will be accelerated due to;

- Quality of product

- Poor storage.

Good storage stability starts with quality product. All 4Farmers products, from our factory and imported, are quality tested and guaranteed.

However, even good quality, well formulated products can struggle in poor storage. So don’t always jump to blaming it was bad product supplied!

Quality of product factors;

- Quality of product ingredients

- Poor formulation resulting in;

- Splitting/layering of formulations

- Fall out

- Changing Physical attributes like increasing viscosity or lump formation

- Poor packaging can lead to;

- Allowing external exchange of material;

- Moisture in

- Solvent or other inerts escaping

- Allowing external exchange of material;

Environmental factors;

- Storage temperature

- High temperature especially is the biggest cause of premature aging. Products like Imidacloprid 600 are especially sensitive if stored or transported in hot conditions.

- Cold conditions can cause crystallization, inactivate emulsifiers and encourage separation.

- Humidity

- Causes caking in dry formulations

- Very low humidity granular can disintegrate to powder

- Sunlight

- Changes colour but usually cosmetic effect

- Note some products photo sensitive products eg Prosulfocarb, Metolachlor

Conclusion

For the majority of products, storage under optimum conditions will ensure that the shelf life extends well beyond the minimum 2 years.

Even good quality product will fail in poor storage.

Elevated temperatures and temperature cycling are the biggest natural enemies of chemical stability.

The advise commonly found on labels is very sound, “Store in closed, original container in a cool well ventilated area, as cool as possible. Do not store for prolonged periods in direct sunlight.”

Cooler Storage Extends Chemical Life

The standard tests for storage stability use a constant 23oC.

The average temperatures of most farm storage maybe around this but the ranges can cycle much higher and lower. Especially high ranging temperature can significantly shorten the life of a chemical.

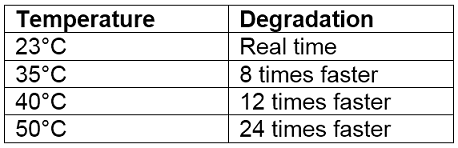

General rules of thumb for degradation of chemical at higher temperatures

You will notice that degradation at higher temperatures isn’t a straight-line response but an exponential one.

Real World Study

4Farmers recently collaborated in a study with Eureka AgResearch on gathering real data in actual farm storage. Temperature loggers were kept in 5 sheds over a range of the WA wheatbelt that tracked temperatures for a whole year.

If we compare chemical stored at a constant and another stored in a shed that accumulates the equivalent of 4 weeks at temperatures over 40°C during its first year of storage, the bottle in the shed is theoretically aged an extra year. In other words, only 1 year stored at a constant 24°C is the same as 2 years in a very hot shed.

The results were influenced by the geography of each site but was also significantly impacted by the design of each shed. Clearly farmers need be mindful of their chemical storage space and definitely avoid situations like the hot sea container in Esperance.

| Temperature | Comments | |||

| Site | Mean | Maximum | Minimum | |

| Gnowangerup | 15.1° | 39.1° | 2.0 | Very good storage conditions by Australian cropping belt standards. Chemical experienced only an occasional and short exposure to temperatures over 35°C and none over 40°C. |

| Esperance | 18.1° | 56.2° | -0.1° | This is worrying storage conditions for agchems. Between September & April a high proportion of the time was spent over 35°C and a significant time was over 40°C. The highest temperature event of 56°C is worrying. There were about 16 events over 50°C. In winter there was an occasional incident of low temperature which included one event below zero. |

| Mullewa | 22.3° | 50.6° | 3.8° | This was worrying storage conditions for agchems. Between September & Early May a high proportion of the time was spent over 35°C and a substantial time was over 40°C. The highest temperature event of 50°C is worrying. It was better than Esperance at least in that this was the only event over 50°C. In winter there was an occasional incident of low temperature. |

| Hyden | 18.4° | 46.4° | 1.8° | By Australian cropping zone standards this was a “normal” shed. That doesn’t mean that it is good, more that it is average. Chemicals were exposed to significant time over 35°C but minimal time over 40°C. There were a few worrying low temperature events. |

| Kalannie | 20.3° | 47.5° | 1.3° | By Australian cropping zone standards this was also a “normal” shed. Chemicals were exposed to significant time over 35°C but minimal time over 40°C. There were a few worrying low temperature events. |

Photo Caption; A large well ventilated light coloured chemical shed like at Gnowangerup can help extend chemical quality in storage